WAMHOFF Holzbearbeitungsmaschinen

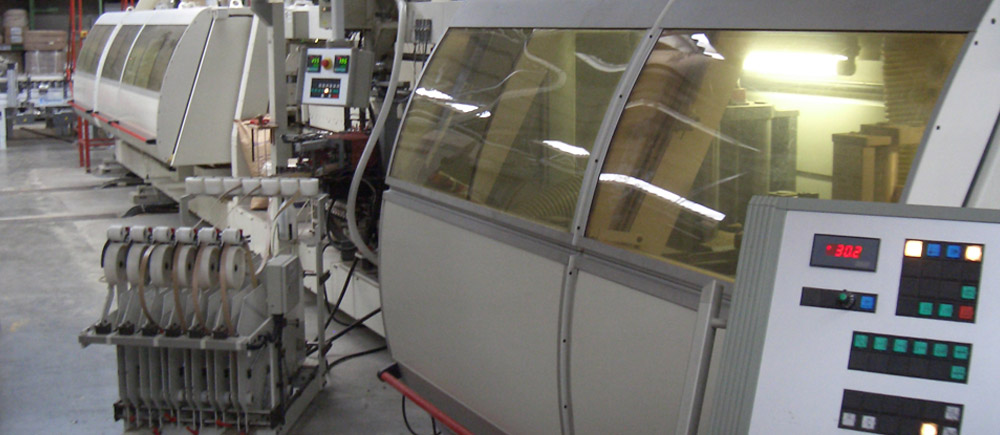

Mit mehr als 40 Jahren Erfahrung in Planung und Abwicklung von individuellen Systemlösungen für die Holzver- und bearbeitende Industrie ist Wamhoff der Partner für Ihr Projekt. Wir liefern modernste Produktionsanlagen, betriebsbereit ab Standort, zu einem optimalen Preis-/Leistungsverhältnis und für unterschiedlichste Anwendungen. Bei uns finden Sie eine große Auswahl gebrauchter Holzbearbeitungsmaschinen führender Hersteller, vom älteren und besonders preisgünstigen Modell bis zur neuwertigen und sofort einsatzbereiten Maschine.

Gegenüber Neuinvestitionen bedeutet das für Sie: Gleiche Sicherheit und Produktivität - Höhere Wirtschaftlichkeit - Geringere Investitionen

Sie haben noch nicht die richtige Maschine für Ihre Produktion gefunden? Unser Team steht Ihnen bei der gesamten Realisation Ihres Projektes mit Rat und Tat zur Seite. Fordern Sie uns!

Gegenüber Neuinvestitionen bedeutet das für Sie: Gleiche Sicherheit und Produktivität - Höhere Wirtschaftlichkeit - Geringere Investitionen

Sie haben noch nicht die richtige Maschine für Ihre Produktion gefunden? Unser Team steht Ihnen bei der gesamten Realisation Ihres Projektes mit Rat und Tat zur Seite. Fordern Sie uns!